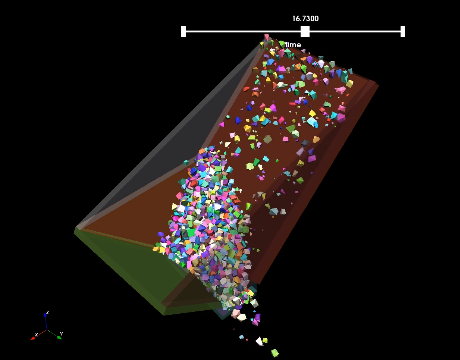

Simulation of fine granular material flow in hoppers / transition chutes.

Mechanical modeling and numerical simulations are tools that can be used to help optimize processes involving granular materials and automated machinery present in belt transport, transfer chutes, grinding, crushing, and particle size separation processes. In particular, mining companies face significant problems when blockages occur in the flow of ore in the hoppers due to the presence of an excessive amount of accumulated material, which requires stopping the process to carry out maintenance tasks.

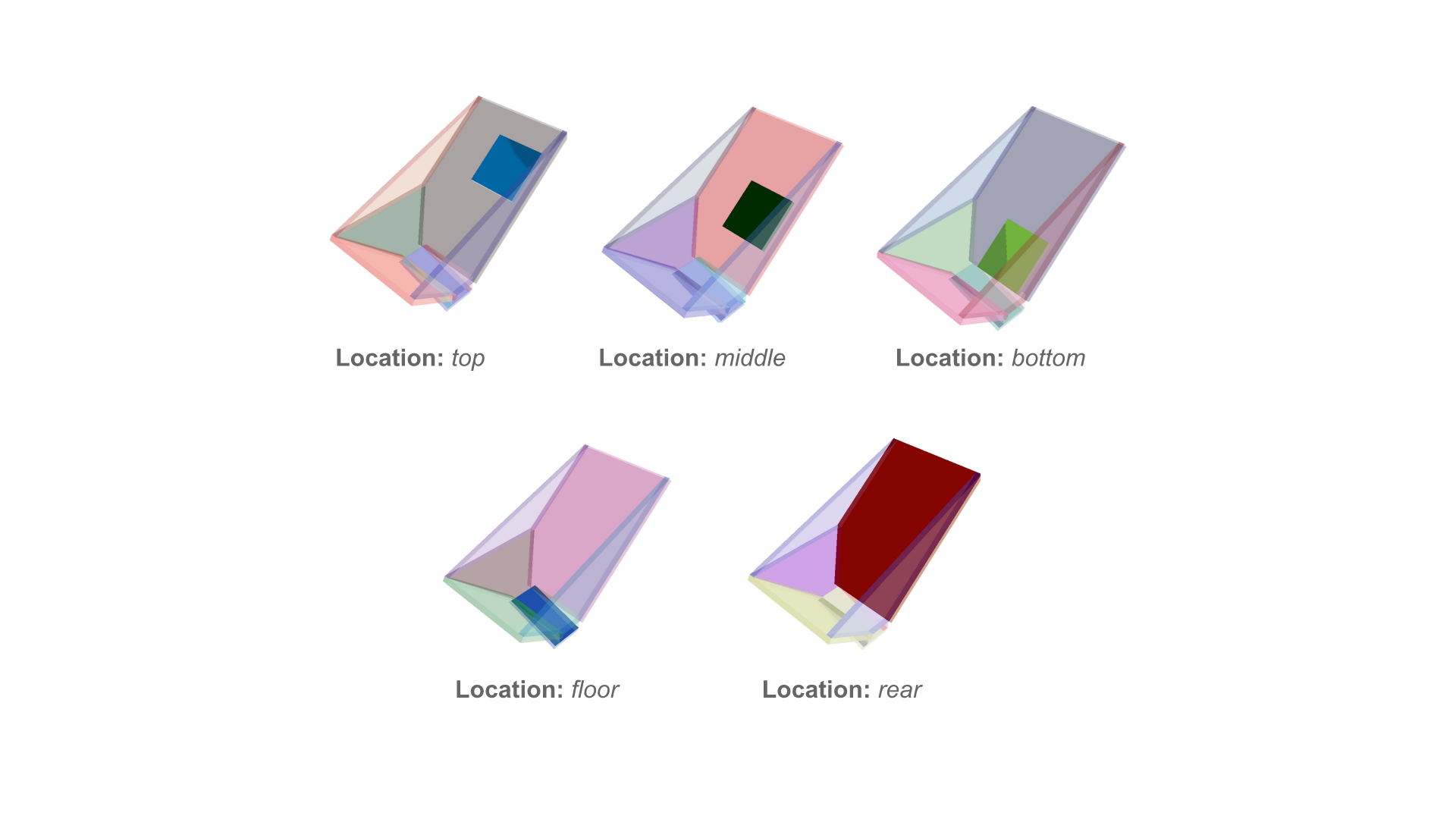

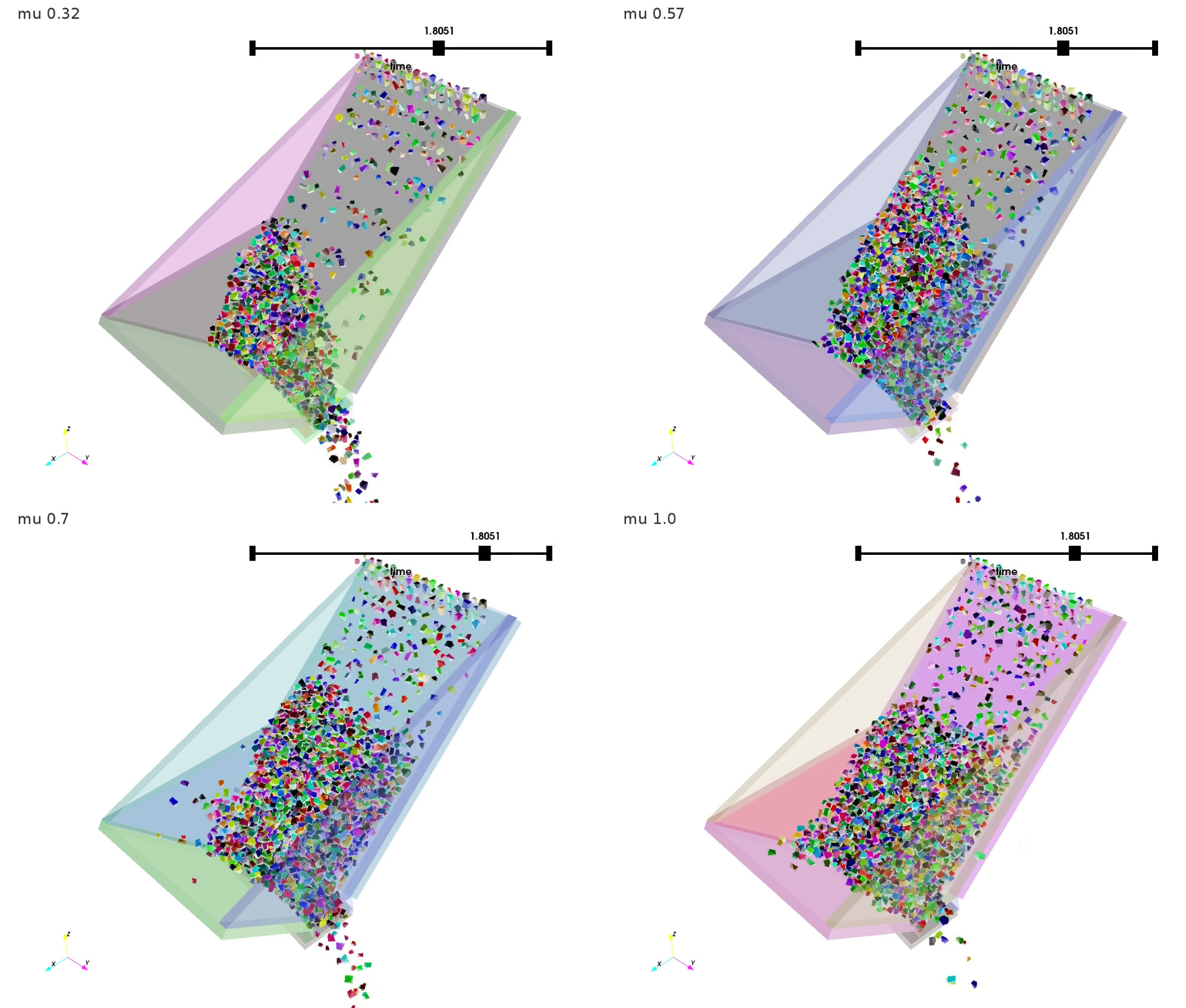

Inria Chile collaborated with PH Engineering in a project to develop computational tools to simulate material runoff in hoppers in order to identify optimal configurations for the installation of vibrators, seeking to minimize the accumulation of material in hoppers. The numerical simulations were performed using parameterizable computational tools, developed by Inria in France, with added functionalities for this process from the work of Inria Chile.